In petrochemical industry, there are many dry gas measurement points, so accurate measurement is needed.

The composition of a medium such as dry gas changes from moment to moment;

Conventional temperature and pressure compensation is not suitable for the medium with the change of composition;

Mass flow does not change with the change of time, space temperature, pressure, measurement applications.

The output frequency of vortex flowmeter represents the volume flow rate under the working conditions flowing through the instrument, and is independent of gas composition, density, etc.

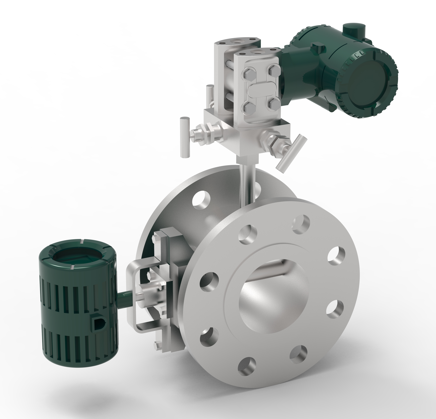

According to Bernoulli equation, the differential pressure signal from the vortex generator in the vortex street flow sensor is proportional to the density of the fluid.

The product of volume flow rate and density is mass flow rate. The mass flowmeter of variable component gas is designed according to this principle.

1.The measured mass flow rate is not affected by the change of components and working condition density;

2.Small permanent pressure loss.

3.Microdroplet has no effect on measurement.

4.Less than half the price of Coriolis mass flowmeter;

5.Can display mass flow cumulative value, mass flow instantaneous value, volume flow, fluid density and other parameters;

6.Accuracy: 0.5 level; Maximum flow rate: 60m/s; Pressure ≤6.4MPa; Medium temperature ≤ 200℃;

The secondary processing of crude oil, such as heavy oil catalytic cracking, thermal cracking, delayed coking, etc., all need to produce a large amount of dry gas (raw gas). These gases have large component differences and wide range of component variation, which is a typical example of variable component gas and the main service object of variable component gas mass flowmeter.

Other components change medium, such as natural gas, blast furnace gas, coke oven gas and other components change medium, choose suitable differential pressure and velocity flowmeters for large diameter measurement.